Recsol’s bimetallic plates establish a product specially designed to resist combined wear by high abrasion and moderated impact. The plates are fabricated through a continuous thermo fusion process (own technolo- gy) with a structural iron base ASTM A36-24, with one or more coating layers, wear resistant (complex carbides and chromium carbides), In this process we uses a robotized and a refrigeration system that allows the formation of CCr, without letting these grow too much, with the purpo- se of generating a better wear resistance. Our plates are coated alloys with a cylindrical shape, subsequently straightening, which allows to close the stress reliefs, and verifies the metallurgic coating union. All our processes are certificated by the ISO 9001-2008.

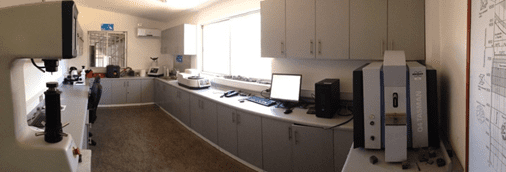

Recsol S.A. owns a laboratory with high-end technology, for metallographic analysis, mea- surement of hardness, and spectrometric. Also, our company owns machinery able to make wear trials according to the ASTM G-65 norm, with the purpose of optimize the research of new alloys against wear and therefore provide the best technical and economical solution, oriented to each specific applications.

In our laboratory, the plates are tested for abrasion of type ASTM G-65 in which we can simulate abrasion, optimizing the different materials that Recsol uses, and extending the useful life of the coated plates and increasing the availability of its equipment.

Recsol offers plates of two different qualities:

R100: Alloy composed of raw materials such as Cr, Mn, Si, and B primary.

Hardness 55-60 HRC

R200: Alloy composed of raw materials such as Cr, Mn, Si, B, Nb and others.

Hardness 58-62 HRC.

Besides having a wide range of formats and thicknesses, we can make specific alloys and thicknesses according to your requirements.

Standard format 2950 x 2250

Chilean fabrication, which allows flexibility of thicknesses, formats, and applications.

Continuous improvements of our raw materials.

Best price/quality relation in plates, generating a better cost/benefit in each application.

Coating chutes, feeders, and all the equipment related to mineral transfer.

Skirt and guiding plates for feeding systems by belting or caterpillars.

Armor compounds of ground movement equipment such as buckets and hoppers.

Wear kit for bucket wheel.